Case Studies

-

Aerospace

GENERAL DYNAMICS

Challenge

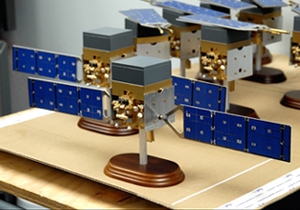

Working with three-dimentional CAD models from General Dynamics, ART was tasked with creating 1:25 scale-models or NASA's Gamma-ray Large Area Space Telescope (GLAST). Our engineers almost immediately encounted a serious complication: when shrunk to scale, certain components - including wafer-thin solar panels became too small and fragile for fabrication.

ART Solution

Improving the original CAD model prior to fabrication enabled ART to create easily-assembled sections for the final desktop models. We consolidated parts and assemblies into 26 components - enlarging and thickening specific details to ensure stability and visibility. Our expert technicians and craftsmen completed 25 scale models.

Results

The models were such a resounding success that a second order for 25 units was placed shortly thereafter.

GENERAL DYNAMICS

Challenge

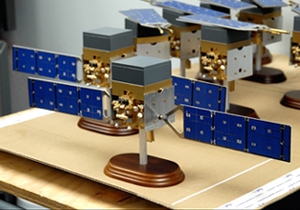

Working with three-dimentional CAD models from General Dynamics, ART was tasked with creating 1:25 scale-models or NASA's Gamma-ray Large Area Space Telescope (GLAST). Our engineers almost immediately encounted a serious complication: when shrunk to scale, certain components - including wafer-thin solar panels became too small and fragile for fabrication.

ART Solution

Improving the orignal CAD model prior to fabrication enabled ART to create easily-assembled sections for the final desktop models. We consolidated parts and assemblines into 26 components - enlarging and thickenng specific details to ensure stability and visibility. Our expert technicians and craftsmen completed 25 scale models.

Results

The models were such a resounding success that a second order for 25 units was placed shortly thereafter.

FROM DESIGN TO DELIVERY

ACCELERATE PRODUCTION CYCLES

ELIMINATE COSTLY TOOLING

TEST DRIVE YOUR DESIGN

© 2023 | Terms of Service | Privacy Policy | Sitemap